Recently added

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Heat Sealers for Film, Bags & Sacks

- E3Hallbrook Pallet Wrap & Ergonomic Solutions

-

Strapping Machines & Strap

- Strapping Materials - Full Pallet Bargins

- Semi Automatic Strapping Machines

- Automatic Strapping Machines

- Fully Automatic Strapping Machines

- Side Seal Strapping Machines semi & automatic

- Corrugated Strapping Machines

- Print Media Strapping Machines

- Pallet Strapping Machines

- Project Strapping Machines

- PP/PET Hand Strapping Tools

- Battery Tension and Sealing Strapping Hand tools for PP & PET Strap

- Steel Strap Hand Strapping Tools

- Strap Wagons and Trolleys

- PP Strapping Materials

- PET Strapping Materials

- WG Strapping Materials

- Steel Strapping Materials

- Seals & Buckles for Strapping

- Corner Protector

- Edge Protector

- STEP Transpak Strapping Machines

- Strapping Rod for Pallet

- Steel Strap Cutters

- STEP Pneumatic tensioners and sealers for PP or PET strap

-

Pallet Wrapping Machines & Stretch Film

- Stretch Film, Machine and Hand Wrap

- Hand Wrap Film and Tools

- Semi Automatic Pallet Wrapping Machines

- Automatic Pallet Wrappers with Remote control

- Fully Automatic Pallet Wrap Machines

- Top film & Dispensers

- Robot Pallet Wrappers

- Options and Data Captures for Wrappers

- Coil Wrapping

- Stretch Hood Pallet Wrapper Lines & Solutions

- Horizontal Wrappers

- Banding Machines & Banding Tape

- String Tying Machine & Packaging Strings

- Heat Sealers for Film, Bags & Sacks

- Bag & Sack Closing Machines - Sewing Machines & Fillers

- Shrink Machines & Shrink Film

- Skin packaging machines

- Robotics, AGV, Load & Conveyor Solutions

-

Multi-head Weigher, Form, Fill and Seal

- Multihead Weighing Machines

- Vertical Form Fill and Seal

- Conveyors and Options

- Rotary Packaging Systems

- Vacuum/Gas horizontal flow packaging

- Full Vertical Automatic Packaging Machine

- Mini Auto Feed Scale Tabletop

- Auger Fillers

- Doybag Solutions

- Packaging Lines for Liquid, Pulp and Paste

- STEP VFFS Best Price Machines in Class

- STEP Y Series VFFS machines

- Auto clipper with count function

- Weighing Machines

- Flow pack from IPS - Italian Packaging Solutions

- Carton Forming and Closing

- Marking & Labeling of products

-

Packaging Materials

- Bags for Packaging

- Banding tape

- Cardboard Boxes

- Corner and Edge Protection

- Document Pouches

- Film knives and Clips removers

- Kraft Paper, Fidele, Packaging Paper

- Labels for Packaging

- Manila labels, Manila clips & Rubber bands

- Packaging Tapes

- PP, PET, Steel strap, WG strap

- Protection in Rolls, foam, card board

- Seals, metal buckels and plastic buckles

- Shrink film

- Stretch film & Hand wrap film

- Strings for Packaging

- Topfilm for pallets

- Tube Film on rolls

- Pharma Packaging

- Packaging Material Production Equipment

- Spare Parts, Components & Used Machines

- Shredder Machines

- Bag Vacuum Packaging

- SOLUTIONS 4 A to Z - How to pack everything

Suppliers

- E3 Hallbrook

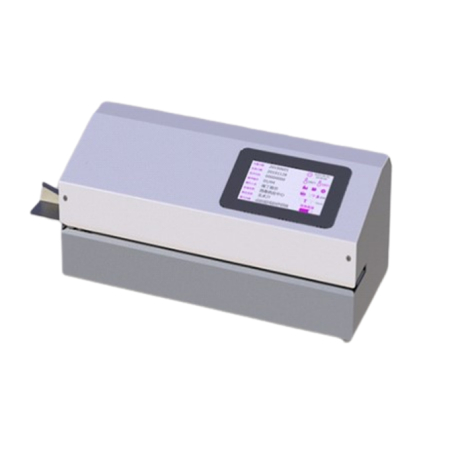

STEP UP 101-CR Printing Medical Sealing Machine (touch screen)

49860020

New

The system provides the required minimum width of the bag based on the content of print, easier for users to define the print content or select appropriate bag. Sealing machine is also equipped with a 7" LCD touch screen for its users. Best for medical/pharmaceutical industry.

Main Characteristics

• 7” color LCD touch screen, graphical operation interface, built-in clock, various working parameters can be set and have automatic storage function;

• The user's usage parameters and the operator, department name, item name and remark content to be printed can be set or changed in English through the built-in color touch control screen, and the corresponding setting contents are printed by the sealing machine;

• It has automatic detection function for sealing machine operation identification, which realizes the detection of equipment running pressure and speed. The parameters of the equipment itself can be displayed instantly. In the test state, the speed, pressure, temperature and test time of the equipment can be printed and saved.

• Computer intelligent temperature control design, working temperature 60~220 °C arbitrarily set, temperature control accuracy ≤±1%;

• It has a fully automatic display error prompt code, which is convenient for users to maintain and detect functions. It can help users quickly find the cause of the fault, with high precision and good stability.

• Self-prepared printing sealing parameter database, record the printing sealing parameters, realize the storage of sealing and printing information, facilitate the traceability query, and meet the needs of sealing quality traceability;

• High-speed heating design: 40 °C to 180 °C only 40 seconds, the common working temperature from 120 °C to 180 °C only 10 seconds, energy efficient, to meet the needs of fast-paced work;

• Auxiliary cooling design: equipped with a microcomputer-controlled cooling mechanism to reduce the waiting time of the high-temperature sealing temperature to the low-temperature sealing temperature. The common working temperature is reduced from 180 °C to 120 °C in 40 seconds, which can effectively improve the working efficiency;

• Safety: When the sealing temperature exceeds the working temperature set value range ±4 °C, the machine will automatically stop working, effectively ensuring the quality of the sealing and the safe operation of the equipment;

• Sealing speed is 10 m/min, using light control technology to realize automatic detection of sealing and printing;

• The sealing width is 12 mm, and the sealing index meets the requirements of the standard "ISO11607-2:2006" and "EN868-5-2009" for the heat sealer;

• The sealing edge is adjustable from 0 to 35mm to meet the needs of users.

• Floating constant pressure pressing structure design, automatic adjustment of heat sealing pressure, sealing pressure exceeds the working range, automatic alarm prompt, adapt to the sealing requirements of three-dimensional bags and different thickness bags;

• Special character input and printing functions with English, numbers and symbols for medical devices used for labeling, marking and providing information for medical devices, which meet the requirements of the health department for sterilization date, expiration date, sterilization batch, pot number Various printing requirements such as pot times, operators, item names, department names, and remarks;

• The expiration date can be automatically adjusted and printed according to the set effective days. The month and month are automatically adjusted to ensure the actual number of days set.

• Double print head configuration, the printing information is doubled, the printing items can be set according to the needs, the printing content can be adjusted, and the double-line printing can be realized. The user can arbitrarily adjust the layout of the printing parameters and decide the position of the printing parameters.

• Self-contained sealing machine English printing system, built-in two 24-pin printers, single-row or double-line printing, clear printing, easy to set up printing items; printable items are: sterilization date, expiration date, sterilization batch , pot number, order, operator, item name and remarks, etc., at the same time can achieve any adjustment of the print information up and down position;

• In order to meet the customer's printing requirements, the device has a reverse printing function for printing information;

• This machine has the function of overheating, temperature failure and pressure fault warning of the print head, which can realize automatic detection during the working process. Various faults can be realized to automatically alarm or prompt the fault code.

• It has three kinds of print font selection forms: narrow body, normal and wide body. At the same time, combined with the printing form of the symbol, it is convenient to print more content to a relatively narrow bag;

• The system will give the print width value according to the selected print content, automatically calculate the minimum bag width, help the operator to determine the number of items printed before printing to select the appropriate package, to achieve the pre-sealing reminder when the package width is insufficient. ;

• The printing function can realize one-button closing or selectively close an item as needed, so that the operator can quickly switch between printing and non-printing;

• With automatic energy-saving standby: adjustable standby time and standby temperature, intelligent standby recovery, photoelectric induction has a bag feeding and can be restored to the working temperature at high speed;

• Adopt advanced flat ceramic heating components, fast heating, uniform heating, high temperature resistance, long service life and high thermal efficiency;

• Complete accessories, optional with the company's special manual cutting machine or automatic roll bag cutting machine, ultra-quiet roller table, dedicated multi-function sealing machine workstation with manual cutting machine and other peripheral configuration, improve equipment Utilization, user-friendly.

Technical Parameters:

• Sealing speed: 10±0.5 m/min

• Sealing edge: 0~35 mm adjustable

• Sealing width: 12 mm

• Dye penetration: the sealing position is not penetrated within 5s

• Sealing strength: ≥250g/inch meets the requirements of YY/T 0698.5-2009 standard

• Working temperature: adjustable from 60 to 220 °C

• Sealing pressure: 90±20 N

• Temperature control accuracy: ≤±1 %

• Printing method: stylus printing (two sets)

• Into the bag direction: the left side into the bag

• AC power supply: 220V±10% 50Hz

• Power: 500 W

• Maximum current: 3.2 A

• Insurance wire: 5A×2

• Weight: 18 Kg

• Dimensions: 560 × 235 × 190 (length × width × height) mm (without guide plate)

30 other products in the same category

E3Hallbrook Ergonomical

Packaging Tables & Solutions

E3Hallbrook Ergonomical

Packaging Tables & Solutions E3Hallbrook Standard Pallet

Wrappers

E3Hallbrook Standard Pallet

Wrappers E3Hallbrook Special Project

Based Pallet Wrappers

E3Hallbrook Special Project

Based Pallet Wrappers

Manual for PP, PET and WG

strap

Manual for PP, PET and WG

strap Battery tools for PET and

PP

strap

Battery tools for PET and

PP

strap Pneumatic tools for PP and

Steel strap

Pneumatic tools for PP and

Steel strap Strap wagons PP, PET, WG

and

steel strap

Strap wagons PP, PET, WG

and

steel strap Steel Strapping Hand

Tools

Steel Strapping Hand

Tools Pallet strap rods

Pallet strap rods Steep Strap Cutters

Steep Strap Cutters Batteries for Battery

Tools

Batteries for Battery

Tools Semi Automatic strapping

machines

Semi Automatic strapping

machines E3 Hallbrook Ergonomic

strapping solutions

E3 Hallbrook Ergonomic

strapping solutions Pallet strapping

machines

Pallet strapping

machines Side seal strapping

machines

Side seal strapping

machines PP Strap materials

PP Strap materials PET Strap

PET Strap Steep Strap

Steep Strap WG Strap

WG Strap Strapping Machines with

Arch

for 9-12-15,5 mm PP Strap

Strapping Machines with

Arch

for 9-12-15,5 mm PP Strap High Speed 5-6 or 9 mm PP

strap

High Speed 5-6 or 9 mm PP

strap Side seal machines PP

Strap

Side seal machines PP

Strap STEP ZD-08 Table Type Mini

Automatic Strapping Machine

STEP ZD-08 Table Type Mini

Automatic Strapping Machine Full Pallet Bargins for

Strap

Full Pallet Bargins for

Strap High speed transit 5-6 or

9mm PP straping machines

High speed transit 5-6 or

9mm PP straping machines Transit PP strapping

machines 9, 12 or 15,5 mm

Transit PP strapping

machines 9, 12 or 15,5 mm Pallet Strapping

machines

Pallet Strapping

machines Project Strapping

Machines

Project Strapping

Machines Fishing and Food

Industry

Fishing and Food

Industry Corrugated industry,

Strapping Machines for

Corrugated industry,

Strapping Machines for Printing Industry

Printing Industry

E3 Wrap 2100 Semi Automatic

Pallet Wrapper

E3 Wrap 2100 Semi Automatic

Pallet Wrapper E3 Wrap 2100 Series Special

Applications and Options

E3 Wrap 2100 Series Special

Applications and Options Hand Film Dispenser For

Hand

Film

Hand Film Dispenser For

Hand

Film Top Film Dispensers

Top Film Dispensers STEP Semi-Automatic

Turntable Pallet Wrapper

STEP Semi-Automatic

Turntable Pallet Wrapper STEP Robot Pallet

Wrappers

STEP Robot Pallet

Wrappers STEP Automatic Pallet

Wrappers with Remote Start

STEP Automatic Pallet

Wrappers with Remote Start Fully Automatic Pallet

Wrapping Lines

Fully Automatic Pallet

Wrapping Lines Stretch Hood Pallet

Wrapping

Stretch Hood Pallet

Wrapping Horizontal Wrappers

Horizontal Wrappers

Banding Materials

Banding Materials Banding Machines Table

Top

Banding Machines Table

Top STEP String Tiers

STEP String Tiers String for Tying

String for Tying

Portable Sealers

Portable Sealers Hand Impulse Sealers

Hand Impulse Sealers Foot Stand Sealer

Foot Stand Sealer I-Bar Impulse Sealers

I-Bar Impulse Sealers Automatic Impulse

Sealers

Automatic Impulse

Sealers Band Sealers

Band Sealers Pharmaceutical Sealers

Pharmaceutical Sealers Tube Film on rolls

Tube Film on rolls Packaging of Food

Packaging of Food Sack Tiers, Drill Tool

Sack Tiers, Drill Tool Bag and Sack closers with

tape

Bag and Sack closers with

tape Bag Closing Machines with

Sewing

Bag Closing Machines with

Sewing Thread for Sewing

Machines

Thread for Sewing

Machines Sack & Bag closing

lines

with sewing machines

Sack & Bag closing

lines

with sewing machines PE Bags for Sealers

PE Bags for Sealers Aluminum Vacuum Bags

Aluminum Vacuum Bags

Polyolefin Shrink Film

Polyolefin Shrink Film PE Shrink Film

PE Shrink Film Heat Shrink Guns

Heat Shrink Guns Skin Packaging

Skin Packaging Shrink Packaging Machines

& Systems

Shrink Packaging Machines

& Systems

STEP AGV Solutions

STEP AGV Solutions STEP Robotics, Robots &

Grippers

STEP Robotics, Robots &

Grippers Belt Conveyors

Belt Conveyors Vibrators, Product feed

& sorting

Vibrators, Product feed

& sorting Vacuum Lifting &

Handling Systems

Vacuum Lifting &

Handling Systems Telescopic Unloading

Conveyors & Systems

Telescopic Unloading

Conveyors & Systems Weighing Scale - Pallet

& Platform Scales

Weighing Scale - Pallet

& Platform Scales

Multihead Weighers

Multihead Weighers Mini Table Top Weighers

Mini Table Top Weighers VFFS Packaging Machines

VFFS Packaging Machines Doybag Packaging

Machines

Doybag Packaging

Machines Flow Pack Machines

Flow Pack Machines Rotary Fillers

Rotary Fillers Vacuum/Gas Horizontal Flow

Packaging

Vacuum/Gas Horizontal Flow

Packaging VFFS Packaging Lines

VFFS Packaging Lines Conveyors for Multihead

& VFFS packaging lines

Conveyors for Multihead

& VFFS packaging lines

Carton Closing

Carton Closing Tape Dispensers

Tape Dispensers Tapemeter

Tapemeter Tapes and Adhesive

Rolls

Tapes and Adhesive

Rolls Protection in Rolls

Cardboard-Bubble-Foam

Protection in Rolls

Cardboard-Bubble-Foam Manual and Pneumatic

Staplers

Manual and Pneumatic

Staplers Carton Erectors

Carton Erectors

Document Pouches

Document Pouches Protection in Rolls, foam,

card board

Protection in Rolls, foam,

card board PP, PET, Steel strap, WG

strap

PP, PET, Steel strap, WG

strap Cardboard Boxes

Cardboard Boxes Stretch film & Hand

wrap

film

Stretch film & Hand

wrap

film Shrink film

Shrink film Topfilm for paller

Topfilm for paller Strings for Packaging

Strings for Packaging Bags for Packaging

Bags for Packaging Seals, metal buckels and

plastic buckles

Seals, metal buckels and

plastic buckles Banding tape

Banding tape Kraft Paper, Fidele,

Packaging Paper

Kraft Paper, Fidele,

Packaging Paper Film knives and Clips

removers

Film knives and Clips

removers Corner and Edge

Protection

Corner and Edge

Protection Manila labels, Manila clips

& Rubber bands

Manila labels, Manila clips

& Rubber bands Labels for Packaging

Labels for Packaging Packaging Tapes

Packaging Tapes

Production Machines for

Sample Making

Production Machines for

Sample Making

Battery for Battery

tensioners and sealers

Battery for Battery

tensioners and sealers Used Packaging Machines

Used Packaging Machines