Recently added

No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

STRING TYING

Get the Best out of String Tying process.

What it can and cannot do.

Typical equipment for the String Tying:

|

|

|

|

| Automatic Felins Pak Tyer 2000-6” |

Automatic Felins Coil Tyer 2000-6” |

Fully Automatic Felins ATS |

Automatisk Felins Rotary Tyer |

Process: The String Tying process starts when the product passes through the machine, in which, the string is tightened by the lead. And then passing the start of keys point and the string is inserted. The attached head node attaches and the string is cut. A new string will then be ready for the next product. Types of string tying materials are LDPE, PET, cotton, elastomer, elastic, viscous and forms as Poly Tape, Twisted Poly and Spiral Twist. The hard products are bound with elastic cords while the soft products are bound with fixed strings.

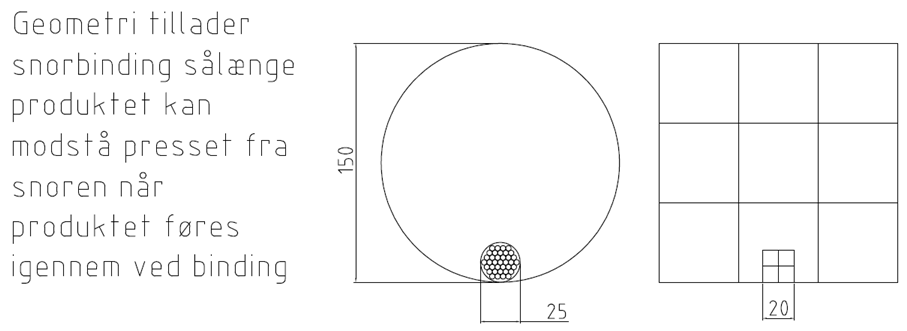

String Tying only has a few restrictions, since it has no direct influence on the product outcome. When the cord/string is tensioned, it is important to note that the product needs to have sufficient hardness be able to resist the pull of the string, while ensuring sufficient tension around the product, thus it is subsequently tied in a bundle. Minimum length of bundle typically down to 20-25 mm, but lesser may be possible. The height of the arm that ties the circles gives the outer limit.

Applicable equipment in relation to different processes:

- Manual:

Manual binding of the products have been around since the first jungle rope, this requires no machinery or equipment. - Semi-automatic:

To my knowledge, there is no equipment for semi-automatic string tying machine. - Automatic:

- String Tying requires an operator. There are 2 main forms:

- The string is placed around the product and is attached to the underside, rotary type. The machines that implement this process is called Rotary Tyers. These machines are often used in the graphics industry, laundries, etc.

- The string is passed down behind the product after it has been inserted into another string. The string passed into the attached head attached and the cord cutters. This type machines that does this process is called linked arm binders. Example machines are Pak Resort 2000 and Coil Resort. These machines are often used in laundries, gardens, cable manufacturers(coil). Alternatives like the right / left version and tandem also apply.

Typical products have been tied with string: - String Tying requires an operator. There are 2 main forms:

- Fully Automatic:

- For laundry, horticulture and industry etc. There is a variety of fully automated solutions where the product is loaded in a position facing the conveyor or on the open belt and then the machine binds the product.

- For laundry, horticulture and industry etc. There is a variety of fully automated solutions where the product is loaded in a position facing the conveyor or on the open belt and then the machine binds the product.

Project specific and more advanced string tying equipment and industry-specific processes can be made on request.

Decommissioning:

Cord/String comes on core typically Ø76 without the core, with cardboard core ø40-50, in a plastic wrapper, often customised for each machine type.

When ordering, the cord/string layup and type of machine is very important to know. You should know in relation to the string tie the string to be used, the number of meters per rewind, termination method, geometric locked or tape.

Elastic String

Elastic String

Related Areas:

Tying with bands which use a plastic "band" being welded.

Wrapping with ribbon by using plastic or paper "band" that being welded.

Author of Article:

Gunnar Salbæk

CEO / Industrial Design with 20 years of experience in the field.

E3Hallbrook Ergonomical

Packaging Tables & Solutions

E3Hallbrook Ergonomical

Packaging Tables & Solutions E3Hallbrook Standard Pallet

Wrappers

E3Hallbrook Standard Pallet

Wrappers E3Hallbrook Special Project

Based Pallet Wrappers

E3Hallbrook Special Project

Based Pallet Wrappers

Manual for PP, PET and WG

strap

Manual for PP, PET and WG

strap Battery tools for PET and

PP

strap

Battery tools for PET and

PP

strap Pneumatic tools for PP and

Steel strap

Pneumatic tools for PP and

Steel strap Strap wagons PP, PET, WG

and

steel strap

Strap wagons PP, PET, WG

and

steel strap Steel Strapping Hand

Tools

Steel Strapping Hand

Tools Pallet strap rods

Pallet strap rods Steep Strap Cutters

Steep Strap Cutters Batteries for Battery

Tools

Batteries for Battery

Tools Semi Automatic strapping

machines

Semi Automatic strapping

machines E3 Hallbrook Ergonomic

strapping solutions

E3 Hallbrook Ergonomic

strapping solutions Pallet strapping

machines

Pallet strapping

machines Side seal strapping

machines

Side seal strapping

machines PP Strap materials

PP Strap materials PET Strap

PET Strap Steep Strap

Steep Strap WG Strap

WG Strap Strapping Machines with

Arch

for 9-12-15,5 mm PP Strap

Strapping Machines with

Arch

for 9-12-15,5 mm PP Strap High Speed 5-6 or 9 mm PP

strap

High Speed 5-6 or 9 mm PP

strap Side seal machines PP

Strap

Side seal machines PP

Strap STEP ZD-08 Table Type Mini

Automatic Strapping Machine

STEP ZD-08 Table Type Mini

Automatic Strapping Machine Full Pallet Bargins for

Strap

Full Pallet Bargins for

Strap High speed transit 5-6 or

9mm PP straping machines

High speed transit 5-6 or

9mm PP straping machines Transit PP strapping

machines 9, 12 or 15,5 mm

Transit PP strapping

machines 9, 12 or 15,5 mm Pallet Strapping

machines

Pallet Strapping

machines Project Strapping

Machines

Project Strapping

Machines Fishing and Food

Industry

Fishing and Food

Industry Corrugated industry,

Strapping Machines for

Corrugated industry,

Strapping Machines for Printing Industry

Printing Industry

E3 Wrap 2100 Semi Automatic

Pallet Wrapper

E3 Wrap 2100 Semi Automatic

Pallet Wrapper E3 Wrap 2100 Series Special

Applications and Options

E3 Wrap 2100 Series Special

Applications and Options Hand Film Dispenser For

Hand

Film

Hand Film Dispenser For

Hand

Film Top Film Dispensers

Top Film Dispensers STEP Semi-Automatic

Turntable Pallet Wrapper

STEP Semi-Automatic

Turntable Pallet Wrapper STEP Robot Pallet

Wrappers

STEP Robot Pallet

Wrappers STEP Automatic Pallet

Wrappers with Remote Start

STEP Automatic Pallet

Wrappers with Remote Start Fully Automatic Pallet

Wrapping Lines

Fully Automatic Pallet

Wrapping Lines Stretch Hood Pallet

Wrapping

Stretch Hood Pallet

Wrapping Horizontal Wrappers

Horizontal Wrappers

Banding Materials

Banding Materials Banding Machines Table

Top

Banding Machines Table

Top STEP M-Series Banders Tape, Label, Stretch, and Automated Stacker Machines

STEP M-Series Banders Tape, Label, Stretch, and Automated Stacker Machines STEP String Tiers

STEP String Tiers String for Tying

String for Tying

Portable Sealers

Portable Sealers Hand Impulse Sealers

Hand Impulse Sealers Foot Stand Sealer

Foot Stand Sealer I-Bar Impulse Sealers

I-Bar Impulse Sealers Automatic Impulse

Sealers

Automatic Impulse

Sealers Band Sealers

Band Sealers Pharmaceutical Sealers

Pharmaceutical Sealers Tube Film on rolls

Tube Film on rolls Packaging of Food

Packaging of Food Sack Tiers, Drill Tool

Sack Tiers, Drill Tool Bag and Sack closers with

tape

Bag and Sack closers with

tape Bag Closing Machines with

Sewing

Bag Closing Machines with

Sewing Thread for Sewing

Machines

Thread for Sewing

Machines Sack & Bag closing

lines

with sewing machines

Sack & Bag closing

lines

with sewing machines PE Bags for Sealers

PE Bags for Sealers Aluminum Vacuum Bags

Aluminum Vacuum Bags

Polyolefin Shrink Film

Polyolefin Shrink Film PE Shrink Film

PE Shrink Film Heat Shrink Guns

Heat Shrink Guns Skin Packaging

Skin Packaging Shrink Packaging Machines

& Systems

Shrink Packaging Machines

& Systems

STEP AGV Solutions

STEP AGV Solutions STEP Robotics, Robots &

Grippers

STEP Robotics, Robots &

Grippers Belt Conveyors

Belt Conveyors Vibrators, Product feed

& sorting

Vibrators, Product feed

& sorting Vacuum Lifting &

Handling Systems

Vacuum Lifting &

Handling Systems Telescopic Unloading

Conveyors & Systems

Telescopic Unloading

Conveyors & Systems Weighing Scale - Pallet

& Platform Scales

Weighing Scale - Pallet

& Platform Scales

Multihead Weighers

Multihead Weighers Mini Table Top Weighers

Mini Table Top Weighers VFFS Packaging Machines

VFFS Packaging Machines Doybag Packaging

Machines

Doybag Packaging

Machines Flow Pack Machines

Flow Pack Machines Rotary Fillers

Rotary Fillers Vacuum/Gas Horizontal Flow

Packaging

Vacuum/Gas Horizontal Flow

Packaging VFFS Packaging Lines

VFFS Packaging Lines Conveyors for Multihead

& VFFS packaging lines

Conveyors for Multihead

& VFFS packaging lines

Carton Closing

Carton Closing Tape Dispensers

Tape Dispensers Tapemeter

Tapemeter Tapes and Adhesive

Rolls

Tapes and Adhesive

Rolls Protection in Rolls

Cardboard-Bubble-Foam

Protection in Rolls

Cardboard-Bubble-Foam Manual and Pneumatic

Staplers

Manual and Pneumatic

Staplers Carton Erectors

Carton Erectors

Document Pouches

Document Pouches Protection in Rolls, foam,

card board

Protection in Rolls, foam,

card board PP, PET, Steel strap, WG

strap

PP, PET, Steel strap, WG

strap Cardboard Boxes

Cardboard Boxes Stretch film & Hand

wrap

film

Stretch film & Hand

wrap

film Shrink film

Shrink film Topfilm for paller

Topfilm for paller Strings for Packaging

Strings for Packaging Bags for Packaging

Bags for Packaging Seals, metal buckels and

plastic buckles

Seals, metal buckels and

plastic buckles Banding tape

Banding tape Kraft Paper, Fidele,

Packaging Paper

Kraft Paper, Fidele,

Packaging Paper Film knives and Clips

removers

Film knives and Clips

removers Corner and Edge

Protection

Corner and Edge

Protection Manila labels, Manila clips

& Rubber bands

Manila labels, Manila clips

& Rubber bands Labels for Packaging

Labels for Packaging Packaging Tapes

Packaging Tapes

Production Machines for

Sample Making

Production Machines for

Sample Making

Battery for Battery

tensioners and sealers

Battery for Battery

tensioners and sealers Used Packaging Machines

Used Packaging Machines